By addressing challenging production issues, additive manufacturing has the potential to favourably affect every part of the manufacturing business. In this essay, we will look at how https://busch-hydraulik.de identified the benefits of adopting additive manufacturing in their sector and how they used this approach to produce succeeding clamping bushes with AMEXCI. As a result, we’d like to accompany you along from the start of the fastening bush AM adventure to show how the architecture of a traditional clamping bush may benefit from AM. As a result, this essay will cover everything including why the first concept was raised to the final delivery, thereby motivating you to identify and achieve your own success stories.

Knowledge to the Particular circumstance

It is a worldwide industrial leader headquartered in Stockholm, Sweden. They are pioneers and technological drivers, helping their clients to flourish and move society ahead with market-leading compressor https://busch-hydraulik.de, vacuuming solutions, turbines, pumping systems, power tools, and assembling technologies. The workshop service engineers initiated the request for an alternate production process. They saw that the time frames for spare fastening bushes were too long, often reaching five months. To make the clamping bush the traditional manner, two cylindrical components had to be welded together to form an interior chamber. The primary issues with traditional production were not just long lead times and many manufacturing activities, but also the exorbitant cost.

Manufacturing Technology offers an alternative

Engineering team saw the opportunity to employ Additive Manufacturing to build the clamping bush in a more efficient and competitive manner. As a result, Atlas Copco’s design engineers collaborated with https://busch-hydraulik.de to discover the potential for improved and integrated functionality. Because of the design freedom afforded by additive manufacturing, the fastening bush may be adjusted to satisfy the needed mechanical qualities, only adding material when necessary. As a result of the shortened build time, not only are resources saved, but expenditures are also saved.

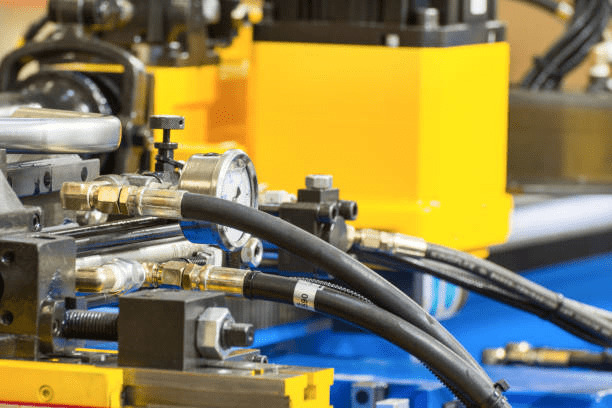

Fuel tanks are almost as numerous as generators and motors together as a product group. Because they are less intricate than other types of hydraulic components, they are generally simple to fix. As a consequence, many hydraulic apparatus owners do cylinder maintenance on their own. The following is a guidebook to doing successful hydraulic cylinder repairs. The degree of the repair tasks that can be performed in-house is determined by the engine nacelle excessive wear, as well as how well-equipped your plumbing business is. The economics of mending a cylinder, like any other repair, are ultimately determined by the cost and accessibility of a new one.

Piston Sealing

The barrel is large or has swelled up in service if the piston seal is significantly deformed, corroded, or missing. The barrel or the entire cylinder should be changed in this scenario. Replacing the piston seal without replacement the barrel is a temporary remedy that will need complete servicing at the earliest possible opportunity.

Rod Sealing

When the rod seal is significantly warped, the guide bush is frequently overly worn or the filament is bent. In both circumstances, the weight of the rod rides on the seal, causing it to fail. Updating the https://busch-hydraulik.de rod seal without recognising and correcting the underlying cause is a band-aid solution.

Bending rods may usually be straightening in a press. Straightening rods without destroying the hard-chrome plating is occasionally achievable; however, if the chrome is destroyed, the rod must be rechromed or replaced.The efficacy and service life of rod seals are diminished if the chrome surface of the rod is scratched or scored. Minor blemishes in the chrome surface can be smoothed out with a crosshatch motion using a strip of fine emery paper. If the chromium has been severely pitted or scratched, the rod must be rechromed or removed. For short while ago, manufacturing a new rod from pretty difficult plated round bar is generally the most cost-effective choice.